AquaFix Curva Shower Cubicle - 1450mmx1000mm L/Hand - Inc. Glass Door

AquaFix Curva Shower Cubicle - 1450mmx1000mm L/Hand - Inc. Glass Door

Our range of tileable shower cubicles will add a professional designer look to any shower room. Includes full installation & drainage kit.

AquaFix Curva Shower Cubicle - 1450mmx1000mm L/Hand - Inc. Glass Door

Included in this kit are the following items:-

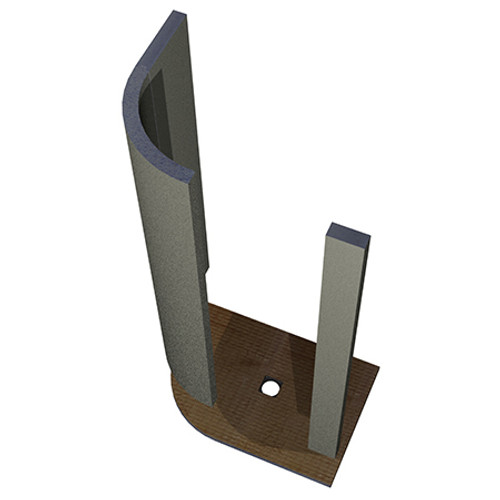

- Curva Cubicle Base - Left Handed

- Curva Cubicle Wall Sections

- AquaFix High Flow Square Waste

- AquaFix Installation Kit

- Curva Glass Door - 672mm x 1900mm x 8mm

You will require the following items to complete the installation of the AquaFix Snail Cubicle:-

- Hard Point Saw

- Bucket

- Solvent Weld Adhesive

- Measuring Jug

- Tape Measure

- Straight Edge

- Junior Hacksaw

- Level

- Sealant Gun

- Breathing Protection

- Pencil

- Paint Brush (wood floors only)

Instruction A – Installation of the standard Curva Cubicle

Step 1

Lay the shower tray into the required position. Through the drain in the shower tray mark the floor to show where the drain will sit. Carefully remove the shower tray and store somewhere safe.

Step 2 - (wood floors only)

If you are installing onto a wooden floor, make sure that the existing floor boards or sheets are fully secured down and as level and flat as possible. Paint the floor area where the shower will sit with the wood floor primer .

PVA MUST NOT BE USED IN PLACE OF THE WOOD FLOOR PRIMER .

Leave to dry for at least 2 hours.

Step 3

Remove flooring as necessary to carry out works to the wastepipe. Please note that if there is a joist in the way of the shower drain base you will need to consult a professional joiner or structural engineer for advice.

Step 4

For water to drain away properly, the wastepipe must have a fall of at least 3cm per metre. Make any alterations to your wastepipe to meet the position marked in step 1. The wastepipe must be properly supported to hold its own weight and that of the shower drain base . Spread solvent weld adhesive around the inside of the shower drain connector . Push the shower drain base onto the shower drain connector with a twisting action. Spread solvent weld adhesive around the inside of the opposite end of the shower drain connector and then slide onto the wastepipe with a twisting action. Once the solvent weld has set; pour water down the drain to check that the waste is not blocked and that there are no leaks.

Replace the flooring ensuring that an adequate hole has been cut to allow for the shower drain base to be exposed through the floor. Smear some lubricant around the black rubber seal on the shower drain base . Please note: The hole size should be no bigger than 180 x 180mm.

Step 5

Put on the protective gloves and wear eye and breathing protection. Mix the 5kg bag of Fix-KST adhesive with approximately 1 Litre of water in a clean bucket which will give the adhesive a stiff consistency. Spread the Fix-KST

adhesive onto the floor of the shower position and drag the notched adhesive trowel across the surface. The notched adhesive trowel will make a ribbed pattern which will leave just the right amount of adhesive on the floor.

Step 6

Place the shower tray into position and bed down onto the adhesive cement. Check that the shower tray is level in both directions using a suitable level.

Step 7

Put your fingers through the drain hole in the shower tray . Push down on the shower tray and pull the shower drain base upwards until it clicks into place into the drain hole in the shower tray.

Step 8

Ease the shower drain internal bowl into the shower drain base . Ease the shower drain internal dome into the shower drain base. When you have finished you can remove the protective gloves and eye and breathing protection.

Step 9

Using a tape measure, measure the distance between the surface of the shower tray and the ceiling. We recommend that you take an additional 5mm from your measurements so that the assembly can be lifted into position more

easily. Carefully mark the cut position on each wall section using a pencil and straight edge. Cut the sections carefully using a hard point saw.

IMPORTANT NOTE: The vertical assembly opening has a strengthening (clear plastic) strip at one, i.e., Wall Section . We strongly recommend that you make note of which side the strengthening strip has been installed as this will not be evident once the cubicle has been tiled. If you plan to install your Curva 1 Cubicle with the optional Flat Roof (EMSC-15-1015 - available to purchase separately through your retailer), you may wish to skip this step and immediately follow Step 10 before then gluing the Flat Roof into position using a thin wavy line of Fix-PU and securing further with 5 No. Board to Board Screws (available to purchase separately).

Step 10

Offer the vertical assembly into place on top of the shower tray and ensure that all components and level using a level. Using a pencil, mark around the vertical assembly on the shower base and at the point where it meets the ceiling*. Set these aside for the moment. Screw 2 No. Straight Mounting Aids into the wall for each side as shown using the pencil marks as a guide; these will offer additional support for the vertical sections.

*If you are installing the Flat Roof option you will not need to mark the ceiling.

Step 11

Apply a thin wavy line of Fix-PU within the marks you made previously in Step 10 then adhere the two vertical sections & to the wall and showerbase. Apply a thin wavy line of Fix-PU across the upright side of vertical section and across the base & ceiling where the section will be positioned then offer the next section into place and apply gentle pressure to bond the sections together.

Step 12

Ensure that the walls are level and that the opening size is square by measuring at various points of the opening, making sure the dimensions remain constant. If you are fitting the Curva 1 Cubicle Frameless Glass Door ref: VEGX-15-1310 (available to purchase separately) you should ensure an opening of 677mm tile to tile. Allow the Fix-PU to set for approx. 3 – 5 hours.

Fitting a steam door?

A Curva 1 Cubicle Door Header Option ref: EMSC-15-1020 (available to purchase separately) can be installed in order to provide a tight door opening size – perfect if you want to use the Curva 1 Cubicle as a steam room. Cut the header to suit your door size and glue into place using Fix-PU. Ensure that the Door Header is held in position with a long screw fixing either side as shown. Allow the Fix-PU to set for approx. 3 – 5 hours after which time the screws can be removed and disposed of.

Step 13

Run a bead of Fix-MD where the vertical assembly meets the shower tray base .

Step 14

From the roll of waterproofing Tape measure and cut a vertical length to the height of the vertical assembly. Put on the protective gloves and wear eye and breathing protection. Put on the protective gloves and wear eye and breathing protection. Using the Pro-SEAL Pre-MIX tape sealer and paintbrush , apply a thin layer of Pro-SEAL tape sealer where the vertical sections meet one another, slightly wider than the Waterproofing Tape width. Bed the Waterproofing Tape into the Pro-SEAL Pre-MIX tape sealer then apply a further thin layer of Pro-SEAL tape sealer over the Waterproofing Tape .

Optional Decor Trim Set (available to purchase separately)

If you have purchased the optional decor trim set, these can be glued into place using Fix-PU. Allow the Fix-PU to set for approx. 3 – 5 hours.

Step 15

Place the disposable tiling aid into the shower drain hole on the shower tray . The tiling aid provides the edge that needs to be tiled up to whilst protecting the drain from debris.

Step 16

After tiling the shower tray the shower drain top can be fitted. Gently place the shower drain top into the shower tray . Measure from the top of the finished tile to the top of the shower drain top . From the opposite end/bottom of the shower drain top mark the same distance as previously measured. Using a hard point saw, cut the excess from the bottom of the shower drain top . Depending on your cutting skill, it may be necessary to file or sandpaper the cut edge to make it completely flat.

Step 17

Place a small blob of tile adhesive in the middle of all four sides of the shower drain hole in the shower tray . Gently ease the shower drain top into position in the shower tray . Leave to set for approximately 3 to 5 hours.

Step 18

Fill the gap between the edges of the shower drain top and the start of the tiles with the same grout used during tiling. Place the shower drain finishing grate into position. Leave to dry for at least 24 hours before using the shower.

Please refer to the instructions that are supplied with the door for specific fitting instructions.

PLEASE NOTE: As discussed in Step 9, there is a strengthening strip in one side of the cubicle; please ensure that the brackets are fitted to this side to support the weight of the glass door.